3D Dynamic Marking Laser 3D Engraving Machine

Ability to adjust focus in real time in the Z-axis (depth) direction to achieve precise processing of curved surfaces or multi-layer materials

Ability to adjust focus in real time in the Z-axis (depth) direction to achieve precise processing of curved surfaces or multi-layer materials

Shallow cutting or texturing is suitable for precision components. Compared with 2D machines, it can process non-planar objects, avoid multiple positioning, and improve efficiency.

3D laser marking machine vs. 2D laser marking machine: 3D laser marking machines can process curved surfaces without tools and are highly efficient; 2D laser marking machines are limited to flat surfaces and require multiple steps.

3D laser marking machine vs. CO2 laser marking machine: 3D laser marking machines are compatible with metals and curved surfaces, while CO2 laser marking machines are primarily used for non-metallic flat surfaces.

3D laser marking machine vs. UV laser marking machine: 3D laser marking machines offer a wider range and lower cost (approximately 1/2 the cost). UV laser marking machines focus on microscopic details but are not suitable for large-scale 3D marking.

3D laser marking machine vs. flying CO2 laser marking machine: 3D laser marking machines emphasize depth and curved surfaces, while flying CO2 laser marking machines focus on high-speed, continuous marking on flat surfaces.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| laser type | Fiber Laser |

| marking area | 110*110-175*175mm |

| Cooling System | Air Cooling |

| key selling points | High Productivity |

| Laser Power | 20W /30w/ 50w(Optional) |

| Laser source | IPG Raycus Max JPT |

3D laser marking machines, due to their adaptability to curved surfaces and high precision, are primarily used in industrial applications requiring marking of complex geometries, particularly in automated production lines. Typical applications include:

Automotive: Marking part numbers and brand logos on curved hoods, wheels, or dashboards, supporting titanium or plastic parts.

Electronics and Semiconductors: Marking 3D QR codes on mobile phone cases, circuit boards, or chip housings, processing curved surfaces.

Medical Devices: Engraving serial numbers on implants (such as heart stents) or surgical tools with guaranteed hygiene and precision (depth control <0.1mm).

Jewelry and Luxury Goods: Engraving 3D patterns or personalized inscriptions on rings and watch cases, suitable for precious metals such as gold and silver.

Aerospace: Marking turbine blades or composite components, providing high-temperature resistant marking.

Consumer Goods: Creating three-dimensional decorations on bottle caps, toys, or packaging, supporting plastic, glass, or wood.

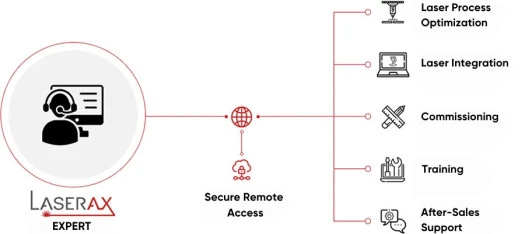

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.