UV laser marking and fiber laser marking machines?

UV laser markers and fiber laser markers are both commonly used laser marking devices in modern indu...

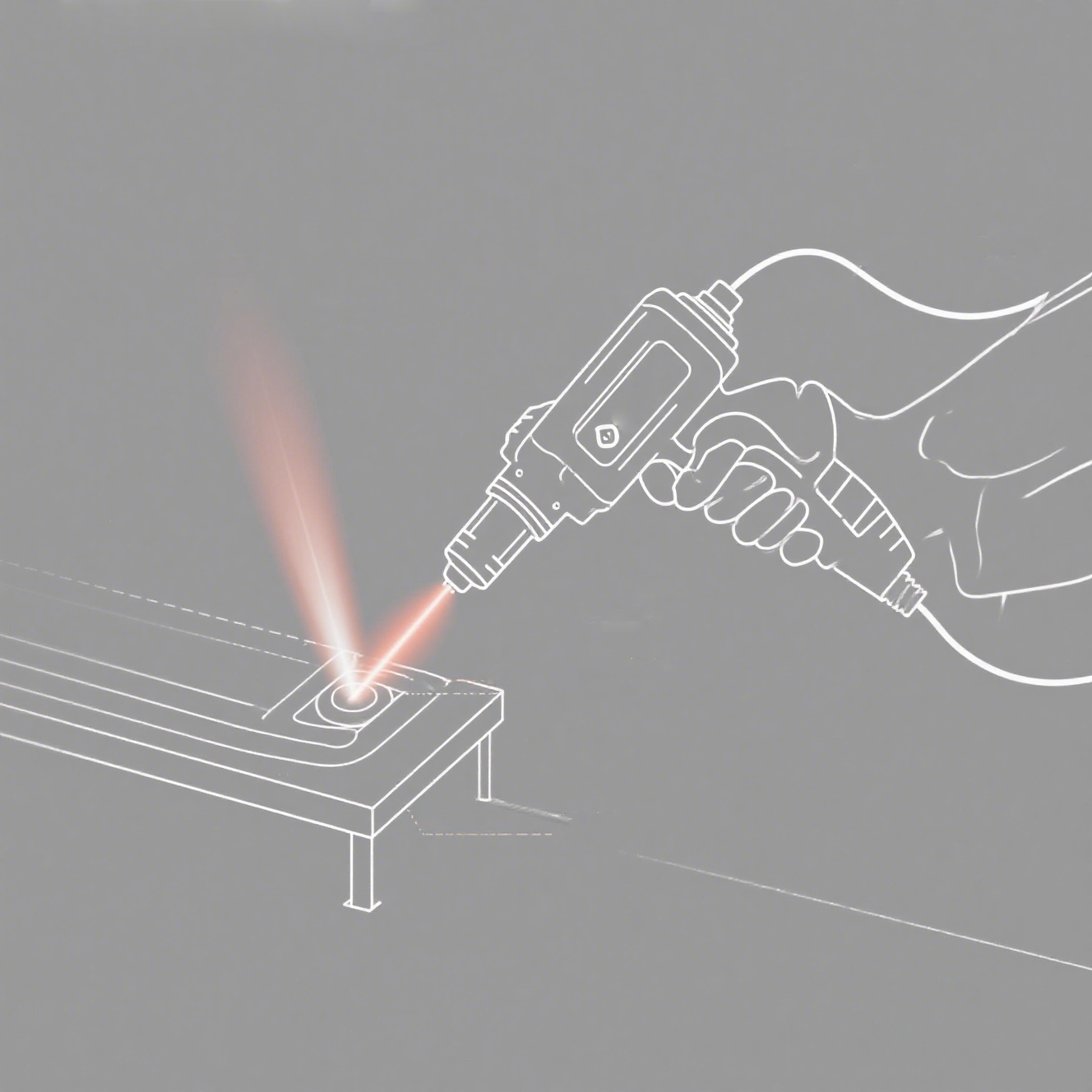

How laser welding works

The core of laser welding is to use the high-energy laser beam generated by the laser to focus on the surface of the workpiece through the optical system to form a high-energy density spot, which triggers the melting or vaporization of the material to achieve welding.

1.Laser generation:Lasers use electrical, optical, or chemical energy to excite working materials (such as gases, crystals, or optical fibers) to produce stimulated emission, forming a high-energy beam.

2. Laser beam transmission and focusing:Transmission: The laser beam is transmitted to the welding head via an optical fiber or lens system, minimizing energy loss.

Focusing: The optical system focuses the laser beam onto the workpiece surface, forming a spot typically with a diameter of 0.1 to 1 mm. After focusing, the laser energy is highly concentrated, sufficient to quickly bring the material to its melting or boiling point.

3.The interaction between laser and materials:Energy absorption: When the laser beam hits the workpiece surface, part of the light energy is absorbed by the material and converted into heat energy. The absorption rate is related to the material type, surface condition (such as roughness, coating) and laser wavelength.

Thermal effect: The absorbed energy causes the surface temperature of the material to rise rapidly, which may lead to melting (a molten pool is formed when the material reaches the melting point, which is suitable for conduction welding) and vaporization (if the energy density is extremely high, the surface of the material may vaporize, which is suitable for deep penetration welding)

4.Molten pool formation and solidification:In deep penetration welding, the molten metal around the keyhole forms a dynamic equilibrium molten pool under the action of the pressure difference inside and outside the keyhole and the surface tension. When the laser beam moves, the molten pool moves with it, and the surrounding materials cool and solidify rapidly to form a weld.

Advantages of laser welding

High Precision: The laser beam can be focused down to the micron level, making it suitable for welding complex structures and tiny components.

Low Heat Input: The heat-affected zone is minimized, reducing material deformation and stress.

Efficient and Flexible: It enables high-speed welding, making it suitable for automated production lines and supporting the welding of multiple and dissimilar materials.

Contactless: No physical contact is required, reducing wear and making it suitable for complex geometries.

Summarize

Laser welding is a unique process. Compared with traditional welding methods, this process has many advantages and is suitable for many fields such as automobile, aerospace, medical and new energy. With the advancement of technology, the application prospects of laser welding will be even broader.