UV laser marking and fiber laser marking machines?

UV laser markers and fiber laser markers are both commonly used laser marking devices in modern indu...

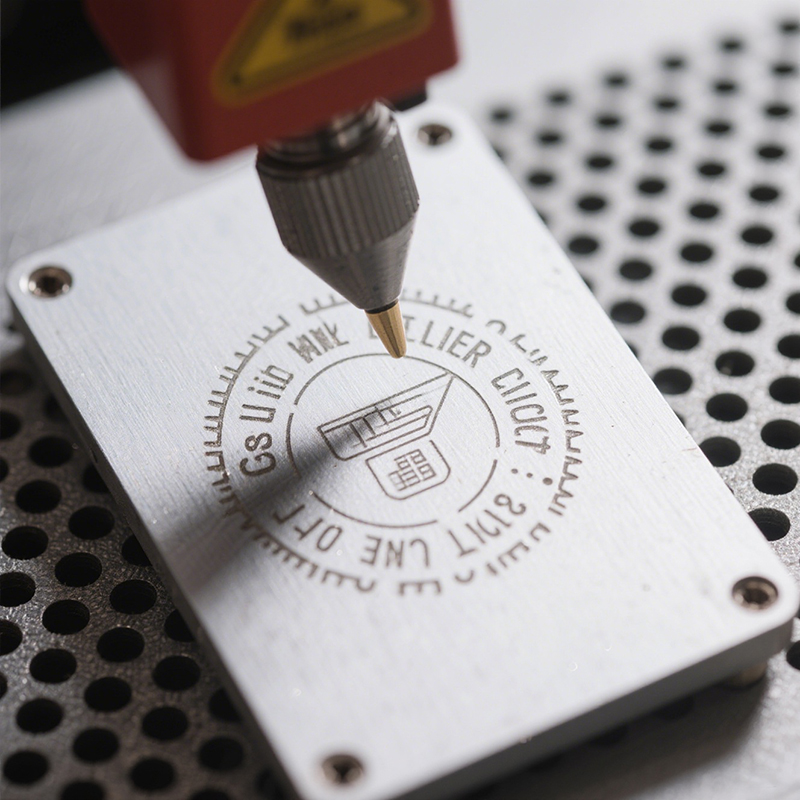

Laser Marking Details

Laser marking uses a laser beam to create a permanent mark (such as text, barcodes, or logos) on a material surface through a thermal or oxidative reaction. Marking depth is typically less than 0.1mm, without removing the material.

Principle:

A laser source (such as a fiber laser with a wavelength of 1064nm) focuses the beam. The material absorbs the energy, causing a color change, foaming, or annealing. For example, metal surfaces oxidize to form a black mark, while plastics foam to form a white mark. The process is non-contact, with an accuracy of 0.01mm and no heat-affected zone (HAZ) expansion.

Advantages:

High Precision and Speed: Marking speeds exceeding 7000mm/s are suitable for mass production, with an error of <0.05mm.

Non-destructive: No damage to the substrate, and the mark is permanent and resistant to corrosion and wear.

Eco-friendly and Economical: No consumables, low energy consumption (1-2kW), and costs 50% less than traditional inkjet.

Flexibility: Applicable to a variety of materials and easily integrated into automated production lines.

Applications:

Industrial Manufacturing: Product serial numbers and barcode markings (e.g., automotive parts and electronic chips) for traceability and anti-counterfeiting.

Medical Devices: Surgical instrument markings, FDA-compliant and contamination-free.

Packaging: Food/drug date markings, high contrast.

Other: Jewelry logos and electronic housing designs.

Laser Engraving Details

Laser engraving uses a laser beam to vaporize or ablate the surface of a material, removing thin layers to create deep patterns or grooves, typically 0.1-1mm deep and tactile.

How it works:

A high-power laser (CO2 or fiber, 50-500W) focuses the beam. The material absorbs the energy and vaporizes (sublimation), forming the grooves. The process removes the material layer by layer, controlling the depth by adjusting the pulse frequency and power. Software generates a 3D path to achieve the relief effect.

Advantages:

Durability: The engraving depth is wear-resistant and suitable for outdoor and high-use environments.

Artistic Effects: Create 3D textures and reliefs with a realistic touch.

Multi-Material Compatibility: Suitable for wood, acrylic, metal, and leather, with a variety of effects.

Customization: Easy to customize and up to five times more efficient than machine engraving.

Applications:

Arts and Crafts: Trophies, wood carvings, jewelry patterns.

Industry: Deep marking on metal parts, texture processing for molds. Advertising/Packaging: Acrylic signs, custom leather.

Other: Phone case designs, glass decorations.

| Aspect | Laser Marking | Laser Engraving |

| Principle | Surface color change/oxidation, no material removal | Vaporization removes the material layer to form a groove |

| Speed | High (7000mm/s+) | Medium to low (<2000mm/s) |

| Accuracy | Very high (0.01mm) | Height (0.05mm) |

| Advantages | Fast, non-destructive, environmentally friendly, and low-cost | Durable, 3D effect, strong artistic quality |

| Shortcoming | Shallow markings, not resistant to extreme wear | Slow speed, great heat damage, and high dust content |

| Application | Industrial identification, anti-counterfeiting, medical devices | Art customization, trophies, mold processing |

| Material | Metal, plastic, ceramic (high absorption rate) | Wood, acrylic, leather, metal (multi-compatible) |

| Cost | Initial cost: RMB 50,000-100,000, low running cost | Initial price: RMB 100,000-200,000, currently under maintenance |

| Laser type | Fiber optic/UV (precision) | CO2/fiber optic (high power) |