Low Power Fiber Laser Marking Machine

The fiber laser marking machine uses a fiber laser to generate a laser beam with a wavelength of usually 1064nm, which is focused by an optical system and acts on the surface of the material.

The fiber laser marking machine uses a fiber laser to generate a laser beam with a wavelength of usually 1064nm, which is focused by an optical system and acts on the surface of the material.

Supports multiple file formats (such as PLT, DXF, BMP), suitable for complex designs

Long laser life (up to 100,000 hours)

Clear and detailed markings, suitable for demanding scenarios

Fiber laser marking machines, thanks to their high precision, high efficiency, and environmentally friendly features, have become the preferred equipment for modern industrial marking. Their wide range of applications and continuously improving technology have given them a significant position in industries such as manufacturing, electronics, and healthcare. Despite a high initial investment, their low maintenance costs and high performance bring significant long-term economic benefits. In the future, with the development of intelligent and portable fiber laser marking machines, they will demonstrate their potential in even more fields, providing strong support for Industry 4.0 and personalized customization.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| Key selling points | High-accuracy and high safety level |

| Graphic format supported | PLT, DXF, JPT |

| Condition | New |

| Type | Fbier Laser |

| Working area | Factory and hardwave products |

| Support Format | DXF PLT JPG PNG |

The versatility and high precision of fiber laser marking machines have led to their widespread application in the following areas:

1. Industrial Manufacturing: Used to mark serial numbers, brand logos, barcodes, or QR codes on parts to enhance product traceability.

2. Electronics: Marking tiny text or images on surfaces such as circuit boards, chips, and phone cases.

3. Medical Devices: Marking surgical tools and medical equipment to ensure legibility and compliance with hygiene standards.

4. Jewelry and Personalization: Engraving personalized designs or text on jewelry and gifts to meet customized needs.

5. Automotive: Marking engine parts and body components to improve production efficiency and anti-counterfeiting capabilities.

6. Packaging: Marking information such as production date and batch number on food and pharmaceutical packaging.

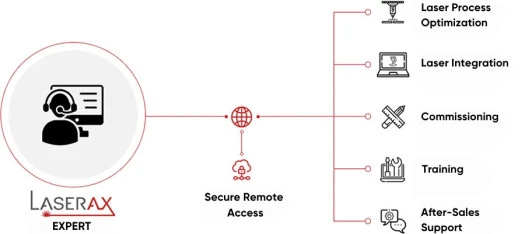

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.