-

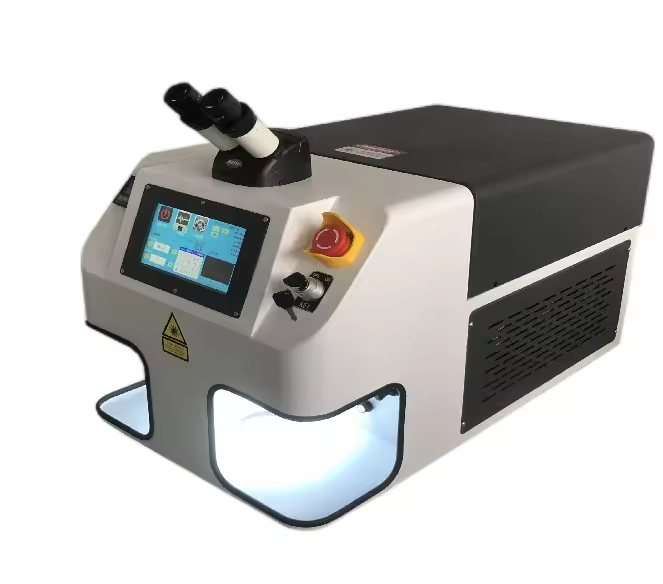

What is the welding quality of laser welding machines? Can it meet industry standards?

-

Modern laser welding machines offer high precision and stability, producing high-quality welds with uniform strength, a smooth appearance, and virtually no weld distortion or spatter. They meet industry standards for most metal materials, such as stainless steel, aluminum, and copper. Different models and configurations can be customized to meet specific welding parameters to ensure optimal results.

-

What materials are suitable for laser welding machines? How thick can the materials be welded?

-

Laser welding is suitable for a wide range of metal materials, including stainless steel, carbon steel, aluminum alloys, copper, and titanium. Most equipment operates within a thickness range of 0.1mm to 10mm, and the welding depth and speed can be adjusted based on the equipment power. The greater the thickness, the more appropriate adjustments to the equipment power and welding time are required.

-

Is the operation complicated? Does it require professional training?

-

The user-friendly interface allows operators to get started in just 1-2 days of training; however, more complex applications require guidance. We provide operator training courses and instruction manuals to ensure operators are proficient in equipment use and understand parameter adjustment, maintenance, and safety measures.

-

Is the equipment difficult to maintain? What is its service life?

-

Laser welding machine maintenance is relatively simple, including regular cleaning of optical lenses, replacement of lubricating oil, calibration of guide rails, etc. Under normal maintenance conditions, the equipment life can reach more than 5-10 years. Good maintenance habits will significantly extend the service life and stability of the equipment.