Portable handheld laser welding machine

The core purpose is to achieve fast and precise welding of metal materials

The core purpose is to achieve fast and precise welding of metal materials

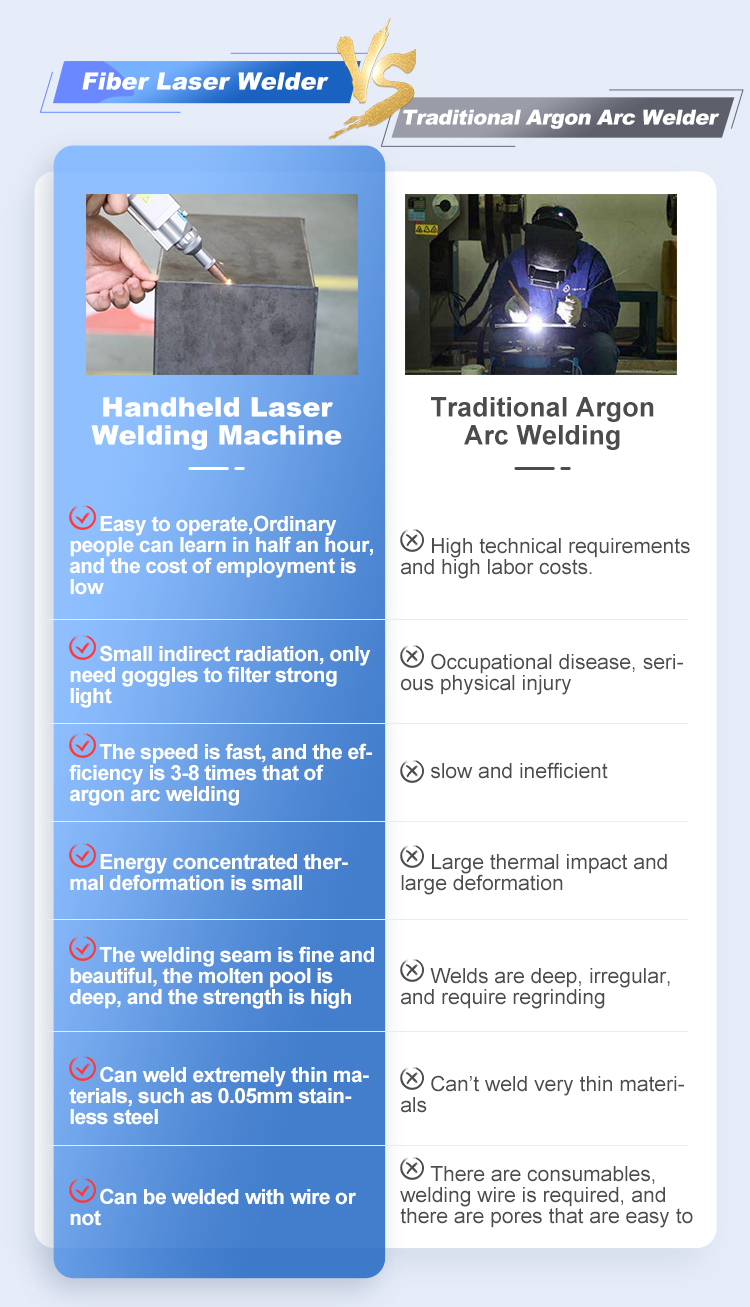

Suitable for repairs in narrow spaces or outdoors; even non-professionals can operate, reducing labor costs; excellent weld quality and no secondary processing; no filler material, reducing oxidation

Handheld laser welders are unique in their portable design and operational flexibility, making them excellent for on-site and small- to medium-sized applications. This stands in stark contrast to desktop laser welders (stationary), automated laser welders (robot-arm), or traditional electric welders (TIG/MIG). The following analysis provides a comprehensive, specific, and comprehensive analysis of their unique features and advantages. These advantages stem from their handheld welding torch and fiber-optic transmission, which are difficult to achieve with other laser welders (such as desktop fixed or automated lines).

Handheld laser welders vs. desktop laser welders: Handhelds offer greater flexibility (mobile welding), while desktops offer high precision but are stationary, making them suitable for large-scale production. Handhelds also cost 50% less.

Handheld laser welders vs. automated laser welders: Handhelds offer ease of operation (manual flexibility), while automated welders offer high efficiency and high volume, but require a high programming threshold and are 2-5 times more expensive.

Handheld laser welders vs. traditional electric welders (TIG/MIG): Handhelds eliminate smoke and spatter, are 10 times faster, and produce aesthetically pleasing welds. Traditional welders exhibit significant thermal distortion and require specialized skills.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| Key Selling Points | Easy to Operate |

| Condition | New |

| Keywords | 1500w 1000w 2000w(Optional) |

| Laser source | MAX Raycus(Optional) |

As a new type of welding equipment, handheld laser welders have gained widespread adoption in various fields due to their flexible operation, fast welding speed, aesthetically pleasing weld seams, and minimal heat-affected zone. Typical applications include:

Automotive and Sheet Metal Industries: Welding of body panels, exhaust pipes, or aluminum alloy components, supporting stainless steel, carbon steel, and aluminum.

Stainless Steel Products: Welding of kitchen equipment, air ducts, and railings, such as 45° tubular upward tilt fixed welding (6G position).

Electronics and Precision Manufacturing: Joining mobile phone cases, battery casings, or circuit boards, and processing brass and aluminum.

Jewelry and Crafts: Precision welding of gold and silver jewelry to prevent heat damage.

Plumbing and Construction: On-site repair of water pipes, steel structures, or stainless steel doors and windows.

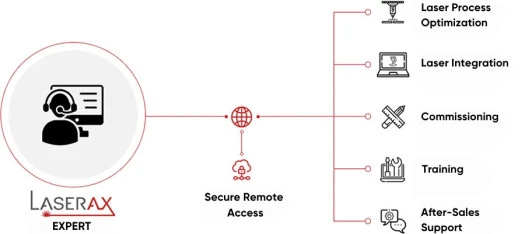

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.