UV laser marking machine

With many years of experience and a professional team, we guarantee the quality of the machines and fast delivery.

With many years of experience and a professional team, we guarantee the quality of the machines and fast delivery.

Extremely low thermal impact, high precision and fine marking, wide material adaptability, permanent marking, and flexible customization.

As an important branch of laser processing technology, the development of UV laser marking machines stems from the overall progress of laser technology. From its initial development in the 1990s to the intelligent stage in 2025, UV laser marking machines have become the core equipment for precision processing. The market is growing rapidly, and the technology focuses on green and efficient production. In the future, it will further integrate the needs of multiple fields and promote industrial upgrading.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| laser type/ laser length | 355mn |

| Laser Power | 3W/5W/7W/8W |

| beam quality M2 | <1.5 |

| frequency | 20-100KHZ |

| marking size | 110x110mm;175x175mm;300x300mm |

| Graphic format supported | AI, BMP, DST, DWG, DXF, DXP, LAS, PLT |

Electronics Industry: Minimal thermal impact, no damage to precision electronic components; high-resolution marking, suitable for tiny designs.

Medical Industry: Corrosion-resistant, high-temperature-resistant, and fade-resistant markings meet stringent medical and hygiene standards; cold processing does not degrade material properties.

Packaging Industry: Beautiful markings without compromising packaging integrity; high absorption rate for transparent and polymer materials, resulting in excellent results.

Jewelry and Luxury Goods: Fine-grained markings with smooth edges enhance product aesthetics and added value; suitable for customized processing of complex designs.

Automotive Industry: Durable markings suitable for harsh environments; cold processing does not affect the optical properties of transparent materials.

Aerospace Industry: High-precision markings with high-temperature and corrosion resistance meet the high reliability requirements of aerospace; cold processing is suitable for composite materials.

Consumer Goods and Daily Necessities: Beautiful, long-lasting markings enhance product quality; suitable for processing a variety of materials.

Anti-Counterfeiting and Product Traceability: Indelible markings provide strong anti-counterfeiting effectiveness; small markings are easily concealed, enhancing security.

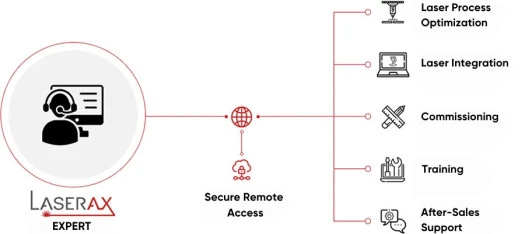

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.