CO2 laser marking machine

It is often used in industrial production to achieve efficient and automated marking.

It is often used in industrial production to achieve efficient and automated marking.

The equipment and maintenance costs are low, and the laser life is long; the galvanometer is controlled by a computer and can be seamlessly integrated with other equipment on the production line to support batch and personalized marking.

CO2 laser marking machines are highly efficient non-metallic material processing equipment. Their unique wavelength and thermal processing principles make them excellent for marking organic materials. Advantages include low cost, high speed, permanent marking, and environmental friendliness, making them suitable for a wide range of applications, including packaging, electronics, and textiles. Their benefits can be maximized through proper parameter adjustment and safety precautions. The core of CO2 laser marking machines lies in their wavelength characteristics, thermal processing principles, and high adaptability to non-metallic materials. These key factors determine their efficiency and uniqueness in specific applications.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| Product name | CO2 Laser Printer |

| Laser Power | 20W /30w/ 50w(Optional) |

| After-sales Service Provided | Online Support |

| After Warranty Service | Online Guide |

| Laser wavelength | 10.64um |

1. Packaging Industry: Marking production dates, anti-counterfeiting codes, or batch numbers on plastic bottles, cartons, and food packaging, ensuring clear and non-destructive marking.

2. Electronic Components: Engraving serial numbers, logos, or parameters on integrated circuits (ICs) and electronic housings (such as plastic or ceramic) to meet high-precision requirements.

3. Wood and Furniture: Engraving patterns, trademarks, or decorative textures on wood products for use in furniture, crafts, or building materials.

4. Textiles and Leather: Marking brand logos or patterns on fabric and leather products (such as shoes and bags) for personalized customization.

5. Glass and Ceramics: Engraving text or patterns on glass bottles and ceramic products for use in wine bottles, tableware, or decorative items.

6. Medical and Pharmaceutical Industries: Marking batch information on drug packaging or medical devices (such as plastic tubes) to ensure traceability.

7. Advertising and Gifts: Creating billboards, gift tags, or seals on acrylic, paper, or rubber.

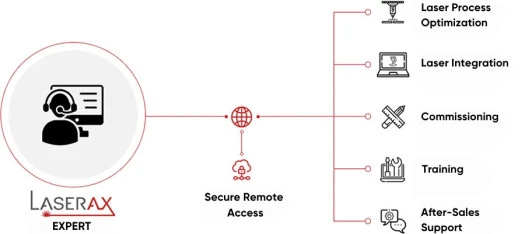

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.