Flying Co2 Laser Marking Machine

Using CO2 gas laser to generate infrared laser beam, mainly for surface treatment of non-metallic materials

Using CO2 gas laser to generate infrared laser beam, mainly for surface treatment of non-metallic materials

The CO2 flying laser marking machine features high-speed scanning galvanometers and USA-imported RF lasers for ultra-high precision marking. It supports various graphics, text, and barcodes with a user-friendly Windows interface. With air cooling, maintenance-free design, and a long service life, it is ideal for industries like tobacco, beverages, and electronics. Certified by CE, ensuring compliance with EU safety standards and providing market access.

The Flying CO2 laser marking machine is a gas laser marking device. Its core is a CO2 laser generator, which electrically excites a CO2 gas mixture to produce a high-energy infrared laser beam. This laser beam is focused by an optical system (such as a galvanometer scanner and focusing lens) before being applied to the material surface, causing a thermal effect (such as vaporization or carbonization), resulting in a permanent mark. Unlike traditional CO2 laser machines, the Flying design allows the laser head to operate synchronously with the moving object. It is typically integrated on a conveyor line, enabling "on-the-fly" marking.

Technical Parameters:

Laser Type: CO2 gas laser, wavelength approximately 10.6μm, suitable for non-metallic materials with high absorptivity.

Power Range: Commonly 10W-60W (e.g., 30W standard configuration). Higher power increases marking speed and depth.

Marking Speed: Up to 7000mm/s, supporting continuous high-speed operation.

Operating Life: The laser has a lifespan of over 20,000 hours, with low maintenance costs. Working Principle: A laser beam rapidly scans through a galvanometer system, while computer-controlled software generates the marking path. The process includes laser excitation, beam delivery, surface energy absorption, and material modification (ablation or oxidation), without requiring filler material or contact with the object.

Device Components: Laser source, galvanometer scanning mirror, F-θ lens, control system, cooling system (air or water), and safety enclosure. Its compact size facilitates integration into production lines.

Price and Specifications: Entry-level equipment ranges from approximately $5,000 to $15,000, depending on power and automation level. It supports multiple file formats (such as PLT, DXF, and AI) and offers marking accuracy up to 0.01mm.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| laser source brand | Coherent |

| Cooling System | 10W 30W Air cooling,60W 100W water cooling |

| key selling points | Easy to Operate |

| graphic format supported | AI, PLT |

| After-sales Service Provided | Online support, Video technical support |

| Laser wavelength | 10.64nm |

Flying CO2 laser marking machines, due to their high-speed, continuous marking capabilities, are primarily used in automated production lines and large-scale manufacturing scenarios, particularly in dynamic environments requiring real-time marking. Typical applications include:

1. Packaging Industry: Marking barcodes or dates on cartons, plastic bottles, and fabric labels, such as in food and beverage production lines, enabling non-stop coding and improving efficiency.

2. Textile and Leather Processing: Marking patterns or dimensions on fabric and leather products for apparel, footwear, or handbag production, supporting continuous processing of large rolls.

3. Wood and Building Materials: Engraving logos or specifications on MDF boards, wood products, or marble, suitable for furniture manufacturing and architectural decoration.

4. Plastic and Acrylic Products: Marking PVC pipes, acrylic sheets, or plastic containers for electronic component housings or medical packaging.

5. Paper and Printing: High-speed marking of book covers, paper labels, or receipts, supporting roll-to-roll production.

6. Other Applications: Electronic product housings, medical device labels, and automotive interiors. In these scenarios, it is often integrated with PLC control systems to achieve fully automated operation, suitable for factory assembly lines, with an annual production capacity of millions of products.

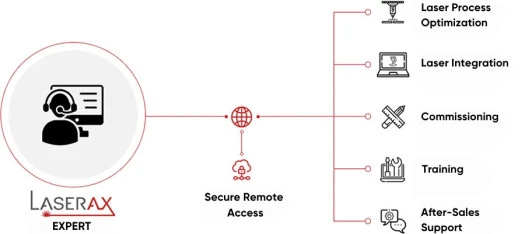

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.