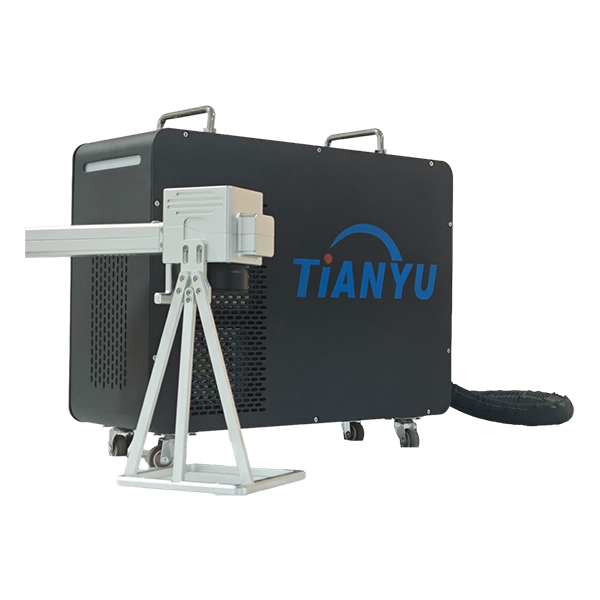

Laser cleaning machine

Laser cleaning is a new and environmentally friendly technology that uses lasers to remove rust, paint, powder coating, oil stains, furniture, and more. Our company offers two types of cleaning equipment: CW (continuous wave) and pulsed laser cleaning machines. CW cleaning typically features high power, such as 1000W, 1500W, 2000W, and 3000W, and is primarily used for rust removal. Pulsed laser cleaning, on the other hand, offers power levels of 50W, 100W, 200W, 300W, and 500W, and is used for applications such as paint, powder coating, and wood cleaning.