200w portable laser paint removal cleaning machine

Customized services available

Pulse laser cleaning machine is a technical equipment that uses high-energy laser pulses to remove dirt, rust, coatings, etc. on the surface of materials. It achieves the cleaning effect by focusing high-energy laser pulses on the target surface, so that the pollutants absorb the laser energy and quickly vaporize or peel off.

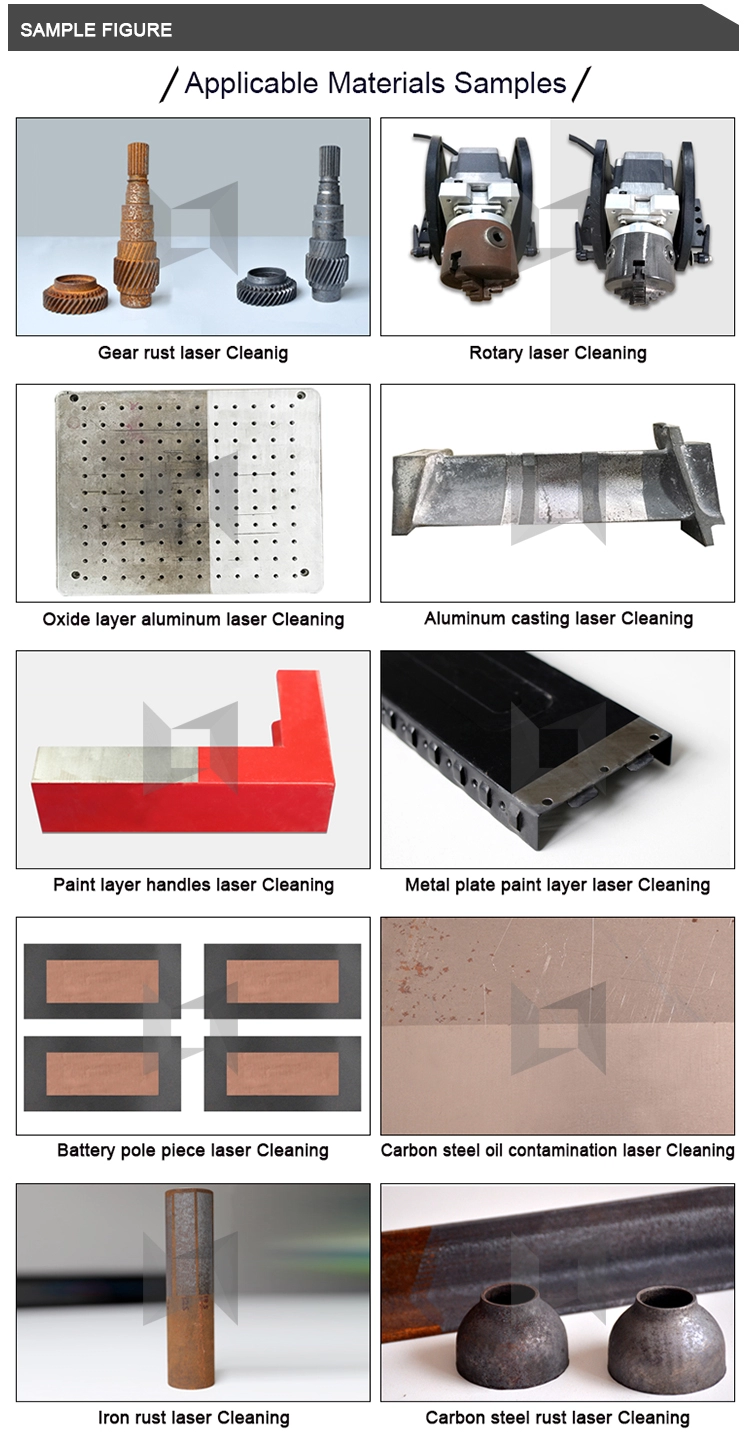

Metal surface derusting, surface paint removal and paint removal, surface oil stains, stains, dirt cleaning, surface coating

removal, welding surface, spray surface pretreatment, stone surface dust and attachment removal, rubber mold residue Clean up,etc.

The series of industrial laser cleaning machine of TYLaser has been widely publicized on the market. Based on users' feedback

and the market research, our company now offers the new laser cleaning machine -TY-C80 to meet the needs of more people on lasercleaning equipment.

The new laser industrial laser cleaning machine is small and portable, the cleaning process is very simple and rapid, the compact

and push-able design can meet your needs for laser cleaning anywhere; and you can adjust the scanning from 1mm to 150mm according to your demands of cleaning different surface area.

Personally review and obtain comprehensive test reports.

| Category | Specifications |

|---|---|

| Laser power | 1000W/1500W/2000W |

| Power | 220v 110v 50HZ 60HZ |

| Laser source | JPT/RAYCUS/Max |

| Scanning Wideth | 10-80mm(optional) |

| Laser Process | Laser cleaning, laser texturing |

| Maximum Part Dimensions | Adaptable |

| Part Material | Aluminum, zinc, magnesium, steel, iron (all metals) |

High Precision: Laser pulses can be precisely controlled, making them ideal for cleaning complex or delicate surfaces, ensuring effective cleaning without damaging fine details.

High Efficiency: Rapidly removes contaminants, significantly improving production efficiency and reducing cleaning time.

Environmentally Friendly: No chemicals are used, and the entire process produces no waste, complying with green environmental protection requirements.

Non-Destructive: Minimal damage to the substrate is achieved, making it particularly suitable for cleaning delicate or valuable items while preserving the integrity of the material.

Flexibility: Adjustable laser parameters allow for adaptability to different materials and cleaning requirements, encompassing a wide range of applications.

Safety: The process is relatively safe, reducing potential safety hazards compared to traditional cleaning methods.

Economical: Long-term operating costs are lower due to reduced maintenance and component replacement.

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.