Pulse laser cleaning machine

Chinese Factory Best Seller High Laser Paint Sppitring Machine Speed Laser Cleaning Machine 1500W Laser Head Air Cooling

Chinese Factory Best Seller High Laser Paint Sppitring Machine Speed Laser Cleaning Machine 1500W Laser Head Air Cooling

Highly efficient, contactless, environmentally friendly, damage-free, environmentally friendly

1. Laser Pulse Generation

Pulsed laser cleaning machines use pulsed lasers (such as fiber lasers or solid-state lasers) to generate short, high-energy laser pulses. These pulses typically last in the nanosecond to microsecond range, with highly concentrated energy, enabling them to deliver a significant amount of energy to the target surface in a very short period of time.

2. Energy Absorption and Thermal Effects

When a laser pulse strikes the surface to be cleaned, surface contaminants (such as rust, paint, and oxide layers) absorb the laser energy. The absorbed energy rapidly heats the contaminant, reaching its vaporization or thermal decomposition temperature. Due to the extremely short pulse duration and concentrated energy, the contaminant can be heated to a high temperature in an instant.

3. Contaminant Removal

Depending on the nature of the contaminant, there are two main removal methods:

Vaporization: For some contaminants (such as paint and coatings), the high temperature causes them to directly transition from a solid or liquid state to a gaseous state, freeing them from the substrate surface.

Debonding: For other contaminants (such as rust and oxide layers), the thermal stress generated by the laser pulse weakens the bond between the contaminant and the substrate, causing it to delaminate, break, and fall off.

4. Substrate Protection

Because the laser pulse duration is extremely short (nanosecond to microsecond), the energy is primarily absorbed by the contaminant. Heat from the substrate surface has little time to dissipate, resulting in a very limited temperature rise. Consequently, the substrate suffers minimal thermal damage, making it particularly suitable for cleaning heat-sensitive materials or where substrate protection is crucial.

5. Precise Control

Pulsed laser cleaning systems can precisely control the cleaning process by adjusting parameters such as pulse frequency, pulse energy, and laser wavelength. This flexibility allows them to adapt to the cleaning needs of diverse materials and contaminants, resulting in widespread applications in industrial manufacturing, cultural relic restoration, and aerospace.

Personally review and obtain comprehensive test reports.

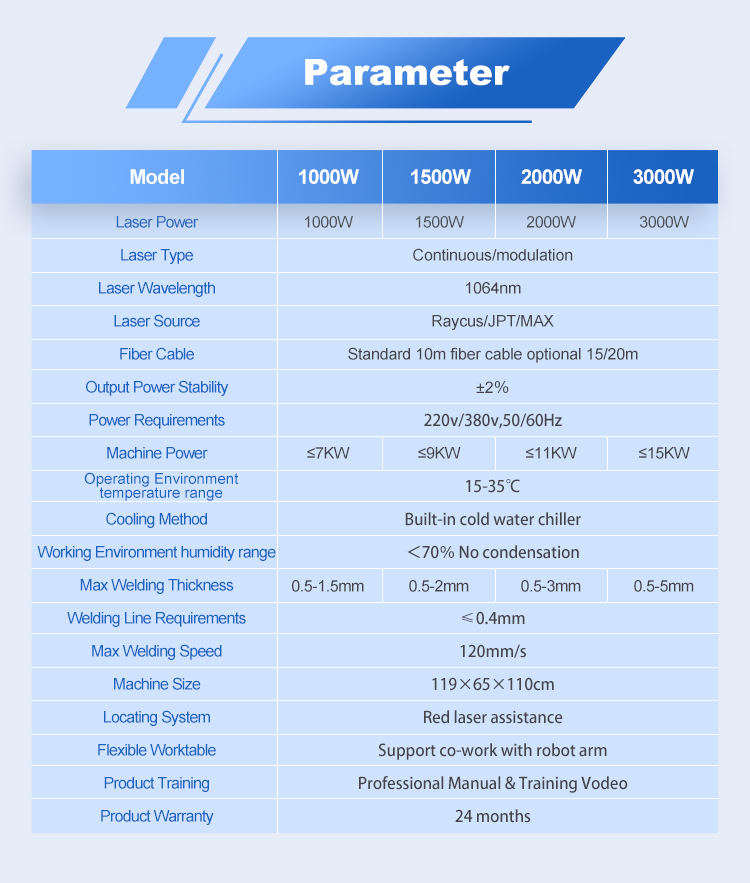

| Category | Specifications |

|---|---|

| Laser power | 1000W/1500W/2000W |

| Laser source | JPT/RAYCUS/Max |

| Warranty | 1 years |

| Marking Process | Laser cleaning, laser texturing |

| Maximum Part dimensions | Adaptable |

Pulse laser cleaning machines are mainly used in industrial manufacturing, cultural relic restoration, aerospace, electronics, automobiles, medical treatment, construction, energy and other fields. Its core function is to remove surface pollutants efficiently, accurately and environmentally friendly, while protecting the substrate and improving surface properties. Compared with traditional cleaning methods, pulse laser cleaning machines have become an ideal choice for modern industry and cultural protection due to their non-destructive, green and high-precision features.

Our experts provide remote support to quickly solve the problems you encounter and help you restart production operations as soon as possible. With the secure remote function of the workstation, they can provide you with comprehensive remote assistance at any time.