Laser welding defect diagnosis and repair

A laser welding machine is an advanced welding device that uses a high-energy laser beam as a heat s...

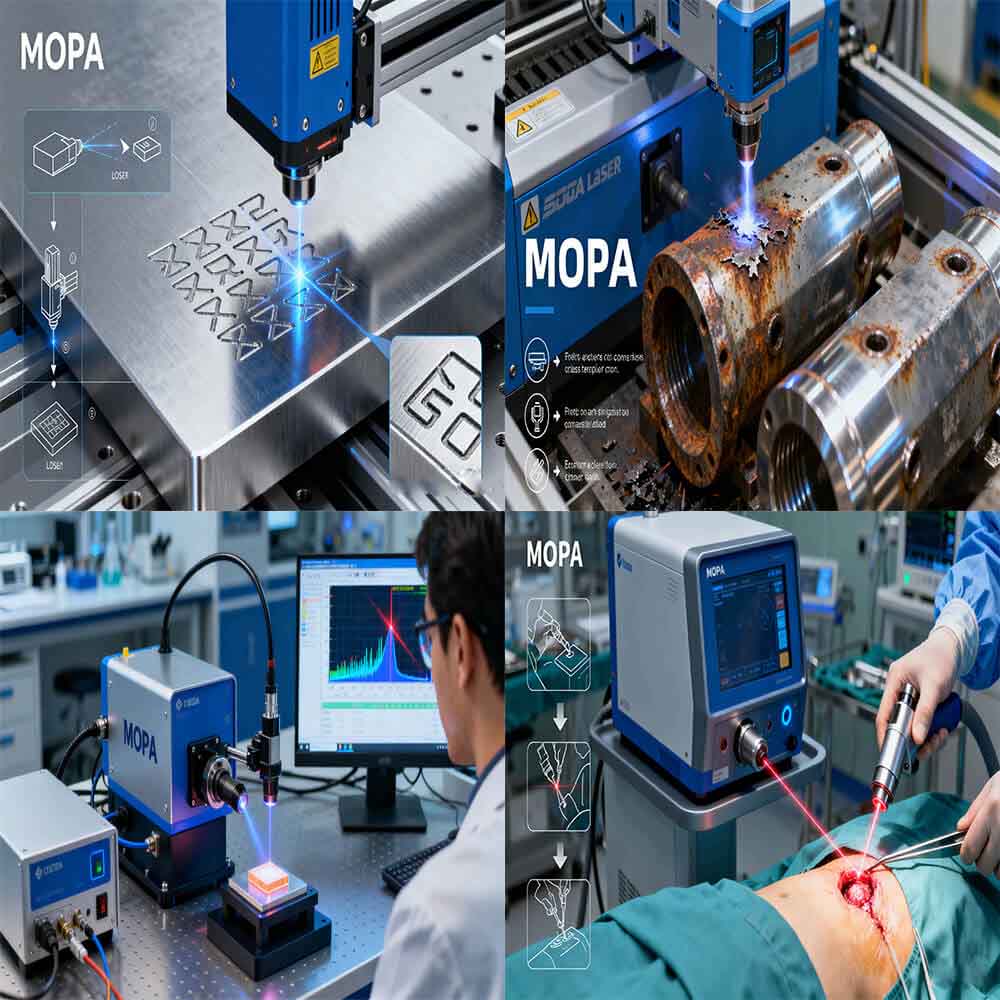

MOPA laser marking machines achieve precise marking on material surfaces through adjustable pulse width and ultra-high repetition frequency. Their biggest advantage is the ability to produce color effects while minimizing heat-affected zones, preventing material deformation or melting. The equipment typically has a power consumption of 20-100W, a compact size, and uses EZCAD or LightBurn software, making it suitable for high-end industrial precision machining.

Difference between MOPA laser marking machine and fiber laser marking machine:

| Aspect | MOPA laser marking machine | Ordinary fiber laser marking machine |

| Laser source type | MOPA (Master Oscillator Power Amplifier, Adjustable Pulse) | Q-switched fiber (fixed pulse) |

| Pulse width adjustment | Adjustable (2-200ns), allowing for flexible control of the thermal effect. | Fixed (100-200ns), narrow adjustment range |

| Frequency range | 1.6-1000kHz, high-frequency precision | 20-80kHz, basically continuous or low frequency |

| Marking effect | Colored, multi-layered (e.g., metallic black/gold/red), with fine, light markings. | Primarily black and white/grayscale, darker colors produce better results but have limited color options. |

| Thermal effect | Low (suitable for plastics/thin materials, no melting/bubbling) | Medium (prone to hot spots/deformation) |

| Applicable materials | Metals, non-metals, plastics, glass (fine/colored) | Predominantly metal, with simple markings |

| Machining accuracy | Height (±0.01mm), beam quality M²<1.1 | Medium (±0.05mm), beam quality M²<1.3 |

| Power range | 20-100W (Precision type) | 20-500W (Industrial Type) |

| Price | Higher | Lower |

| Applicable Scenarios | Fine craftsmanship, color marking, medical/electronic | Mass production of black and white markings, industrial parts |

| Shortcoming | High cost | Limited color options, large heat-affected zone |

Application scenarios of MOPA laser marking machine: