Laser welding defect diagnosis and repair

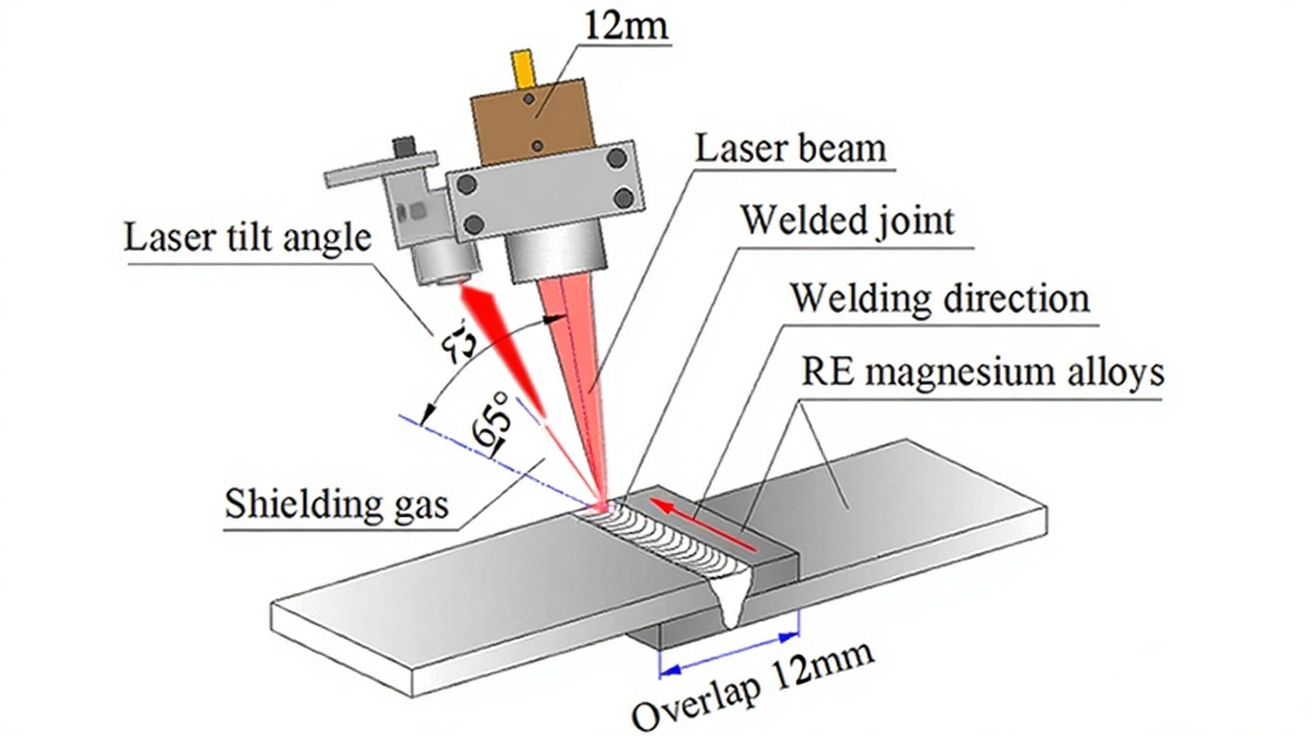

A laser welding machine is an advanced welding device that uses a high-energy laser beam as a heat s...

Laser welding, as a high-precision and high-efficiency joining technology, is widely used in fields such as automotive, aerospace, electronics, and medical devices. However, defects inevitably occur during the welding process. If these defects are not diagnosed and repaired promptly, they can lead to structural failure or safety hazards. This article will begin by discussing the types of laser welding defects, and then progressively explore their causes, diagnostic methods, repair strategies, and preventive measures. Through a multi-faceted approach, and using illustrations and tables, we aim to help you comprehensively understand and master the relevant knowledge. If you are a welding professional or business owner, this article will provide you with practical guidance.

1.Types and causes of defects in laser welding:

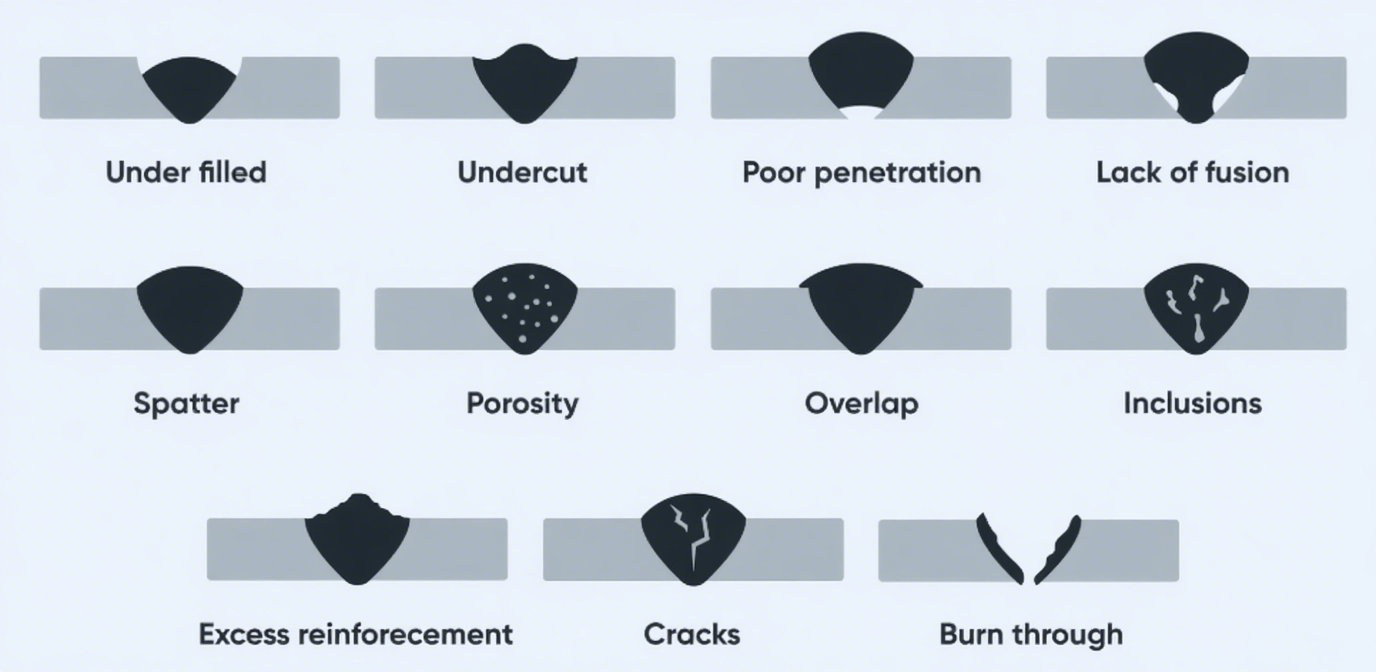

Laser welding defects typically stem from improper process parameters, material issues, or environmental factors. These defects can be broadly categorized into macroscopic defects (such as cracks) and microscopic defects (such as pores), influenced by factors including laser power, welding speed, shielding gas, and material purity. Understanding the types of defects is fundamental to diagnosis and repair. The table below summarizes a multifaceted interpretation of common laser welding defects, including their types, causes, and potential impacts.

| Defect type | Main causes | Potential impact | Example materials |

| Porosity | Gas inclusions (such as hydrogen or nitrogen) or excessive welding speed can prevent gases from escaping. | Reduces strength and causes corrosion. | Stainless steel, aluminum alloy |

| Cracks | Excessive thermal stress, high material thermal sensitivity, and uneven cooling rate. | Structural fracture, fatigue failure | Titanium alloy, high-strength steel |

| Undercut | Excessive laser power and focus misalignment lead to excessive melting at the edges. | Stress concentration, thinning of welds | Sheet metal |

| Lack of Fusion | Insufficient power, excessive clearance, or excessive speed. | Insufficient weld strength | Thick plate welding |

| Spatter | Improper shielding gas, surface contamination | Rough surface, affecting the appearance. | Carbon steel |

Analyzing the causes from multiple perspectives: process parameters (such as insufficient power leading to lack of fusion) are the dominant factor, followed by material factors (such as alloy composition), and environmental factors (such as humidity causing porosity) play a supporting role. Proceeding step by step, we first identify macroscopic defects, and then delve into microscopic analysis.

2.A multifaceted interpretation of defect diagnosis methods:

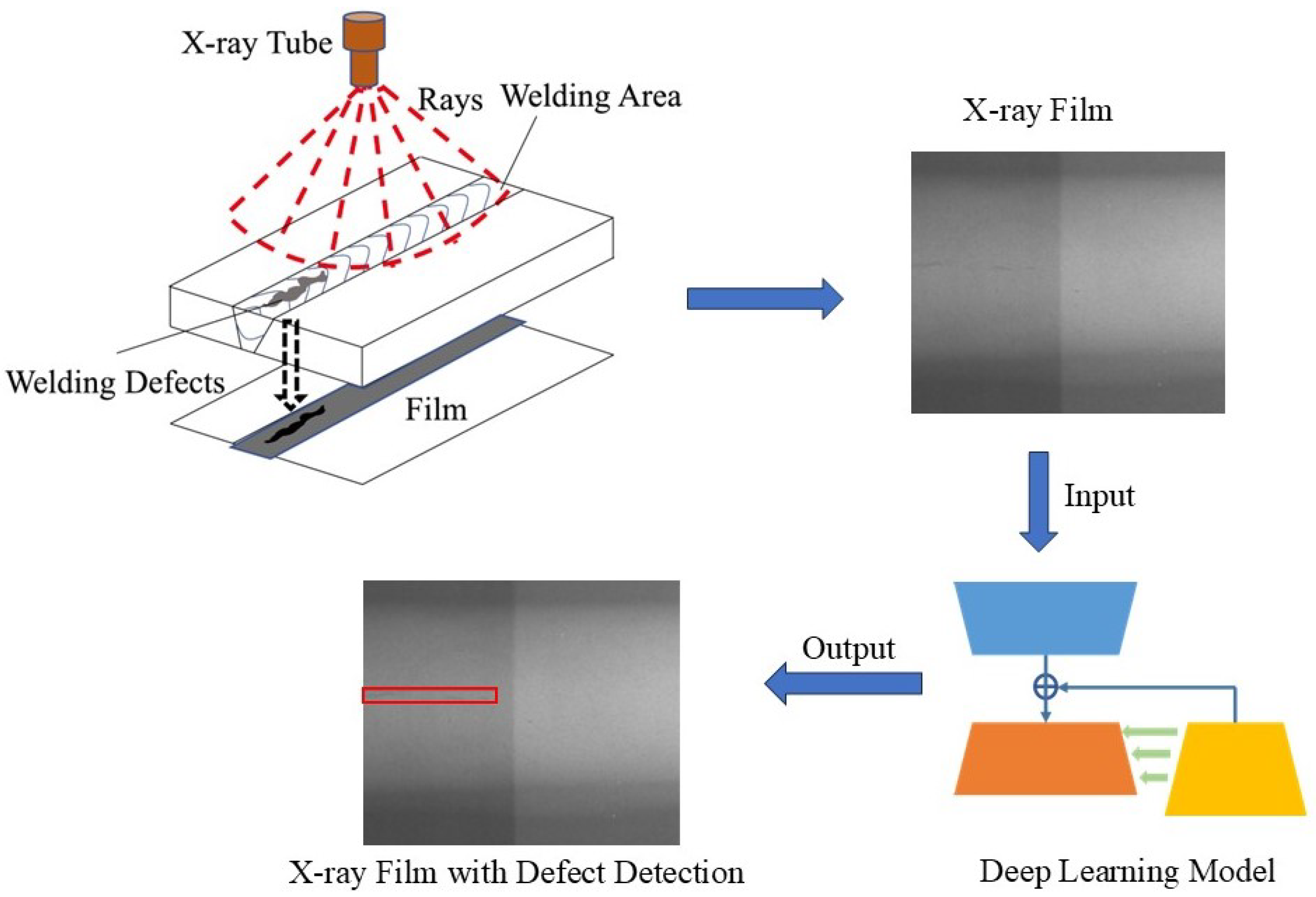

Diagnosis is the prerequisite for repair. Laser welding defect diagnosis can be divided into non-destructive testing (NDT) and destructive methods. From various perspectives, non-destructive methods are suitable for online inspection, while destructive methods are used for laboratory verification. The diagnostic process is progressive: starting with visual inspection, progressing to advanced imaging techniques, and finally to data analysis.

| Diagnostic methods | Applicable defects | Advantage | Shortcoming |

| Visual inspection | Surface cracks, undercut, and slag spatter. | Simple and economical | Internal defects cannot be detected. |

| X-ray inspection (X-ray Radiography) | Pores, cracks, lack of fusion | High resolution, internal visualization | Radiation risks, expensive equipment |

| Ultrasonic Testing | Internal cracks, pores | Radiation-free, real-time | Requires coupling agent, and demands high surface quality. |

Magnetic Particle Inspection | Surface cracks (applicable to magnetic materials) | High sensitivity | For magnetic materials only. |

AI-based Detection | All defects | Automated, high accuracy | Training data is needed. |

Ultrasonic testing analyzes internal defects through waveform analysis, and when combined with AI, it can achieve intelligent diagnosis.

Interpreting from multiple perspectives: Diagnosis should combine various methods, progressing step by step—first using visual preliminary screening, then confirming with NDT (non-destructive testing), and finally verifying the severity with destructive testing. This helps avoid misdiagnosis and improves efficiency.

3.A layered and progressive approach to defect repair strategies.:

Repairing defects requires selecting a strategy based on their type and severity. From a multifaceted perspective, repair methods include mechanical techniques (such as grinding) and heat treatment (such as re-welding). The process is progressive: defect assessment → method selection → repair execution → post-repair verification.

| Defect type | Repair methods | Step | Precautions |

| Stomata | Remelting welding or filling | 1. Clean the surface; 2. Adjust parameters and re-solder; 3. Cool down. | Control the gas flow to prevent secondary porosity. |

| Crack | Grinding and re-welding | 1. Remove the cracked area; 2. Preheat the material; 3. Perform low-power welding. | Monitor stress to prevent further expansion. |

| Biting edge | Repair welding and filling | 1. Clean the edges; 2. Fill the weld pool; 3. Grind and smooth the surface. | Match the base material to avoid color differences. |

| Unfused | Reweld | 1. Increase the gap; 2. Increase the power; 3. Test the strength. | Ensure uniform penetration depth. |

| Slag splashing | Mechanical removal | 1. Grinding or sandblasting; 2. Surface treatment | Protect the weld seam from damage. |

Multi-faceted approach to repair: economic considerations (prioritizing mechanical repair for minor defects), safety considerations (re-welding requires specialized equipment). A step-by-step process ensures that the repair does not introduce new defects.

4.Parameter optimization and defect prevention:

Prevention is better than repair. By optimizing laser welding parameters, defects can be reduced at the source. Parameters analyzed include power, speed, focus, and gas. Simulation software can predict defects, allowing for adjustments based on experience.

The prevention strategy is implemented in a step-by-step manner: 1. Material preparation (surface cleaning); 2. Parameter testing (sample welding); 3. Real-time monitoring (sensor feedback); 4. Regular equipment maintenance.

Summary: Comprehensive management of laser welding defects

Laser welding defect diagnosis and repair is a systematic process, forming a closed loop from defect identification to prevention. Through multi-faceted analysis and a step-by-step approach, you can effectively improve welding quality. If you encounter problems in your practical operations, please feel free to contact us for customized solutions. Keep learning, and welding technology will help your business thrive!