Laser welding defect diagnosis and repair

A laser welding machine is an advanced welding device that uses a high-energy laser beam as a heat s...

Laser marking originated from the invention of the laser in the 1960s and has become a core tool of Industry 4.0 by 2025. This article will explore various aspects of laser marking technology. If you are interested in laser technology or want to know how to apply it to your work, this article will provide you with valuable information. Feel free to contact us privately to discuss related matters!

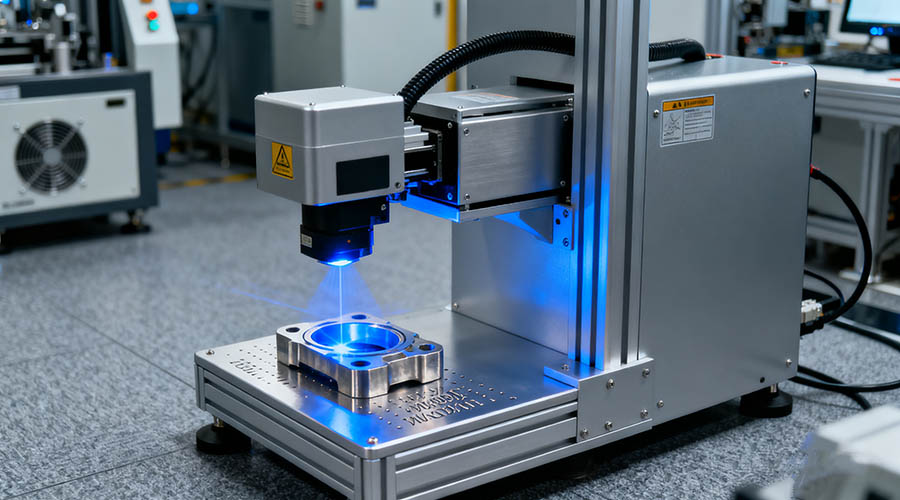

What is laser marking?

Laser marking is a technique that uses a high-energy-density laser beam to locally irradiate a workpiece, causing the surface material to vaporize or undergo a chemical reaction that changes color, thus leaving a permanent mark. The core principle of this technology is based on the interaction between the laser beam and the material surface. When a high-energy-density laser beam irradiates the material surface, various physicochemical changes occur, including melting, vaporization, and oxidation, thereby forming a permanent mark.

Working principle of laser marking?

Laser marking works by using a high-energy laser beam to engrave or mark on a material surface. When the laser beam is focused on a small area, it releases enormous energy, causing physical or chemical changes on the material surface, thus forming a permanent mark.

Types of laser marking

| Type | Laser source characteristics | Wavelength | Applicable materials | Marking depth |

| Fiber laser | High power and long lifespan (>100,000 hours) | 1064nm | Metals (steel, aluminum, copper), plastics | Light to medium (0.01-0.5mm) |

| CO2 laser | Gas discharge, cutting and marking | 10.6μm | Non-metallic materials (wood, leather, paper, glass) | Shallow (0.01-0.1mm) |

| Ultraviolet laser | Cold working, low heat effect | 355nm | Plastics, glass, silicon wafers | Extremely shallow (<0.01mm) |

| MOPA Laser | Adjustable pulse width, color effect | 1064nm | Stainless steel, aluminum alloy | Shallow (0.01-0.1mm) |

| Field | Specific applications | Advantages | Example |

| Automobile manufacturing | Engine parts, wheel serial numbers | High temperature resistance and corrosion resistance | Tesla uses fiber lasers to print VIN codes, marking millions of items annually. |

| Electronics 3C | Phone case, PCB QR code | High precision, anti-counterfeiting | Huawei's supply chain uses MOPA laser-engraved color logos with a precision of 0.01mm. |

| Medical devices | Surgical scalpel, implant UDI code | Biocompatible and pollution-free | Johnson & Johnson uses UV laser to label stents, which meet FDA standards. |

| Food packaging | Bottle cap date code, barcode | Environmentally friendly, inkless | Coca-Cola uses CO2 laser marking on PET bottles, with an annual production capacity of hundreds of millions. |

| Jewelry craftsmanship | Gold ring setting mark | Beautiful and wear-resistant | Tiffany uses green laser to engrave serial numbers. |

| Aerospace | Turbine blade part number | High strength, no damage | Boeing uses YAG laser to mark titanium alloy parts |

| Advantage | Explain | Quantifying benefits |

| High-efficiency automation | Speed 10k characters/second, supports robot integration | Production efficiency increased by 5 times, downtime decreased by 80%. |

| Permanent durability | Markings are wear-resistant and chemically resistant. | Lifespan > 20 years, excellent anti-counterfeiting effect |

| Environmentally friendly and energy-efficient | No ink/chemicals, zero waste | Compliant with REACH/FDA, saving 100,000 yuan annually in consumables. |

| Precise and flexible | Minimum line width 0.01mm, compatible with multiple materials. | Applicable to 90% of materials, highly customizable |

| Low maintenance | Laser source lifespan > 100,000 hours | Annual maintenance fee < 5000 yuan |

Tianyu Laser meets all your needs.

Tianyu Laser meets all your needs.If you have any questions, please click the image below to contact us. We will provide you with the most satisfactory solution and preferential information!